The Hossfeld Bender Manual is a comprehensive guide for operating, maintaining, and troubleshooting the Hossfeld Universal Bender. It ensures safe and efficient use, covering setup, tooling, and advanced techniques.

Overview of the Hossfeld Bender

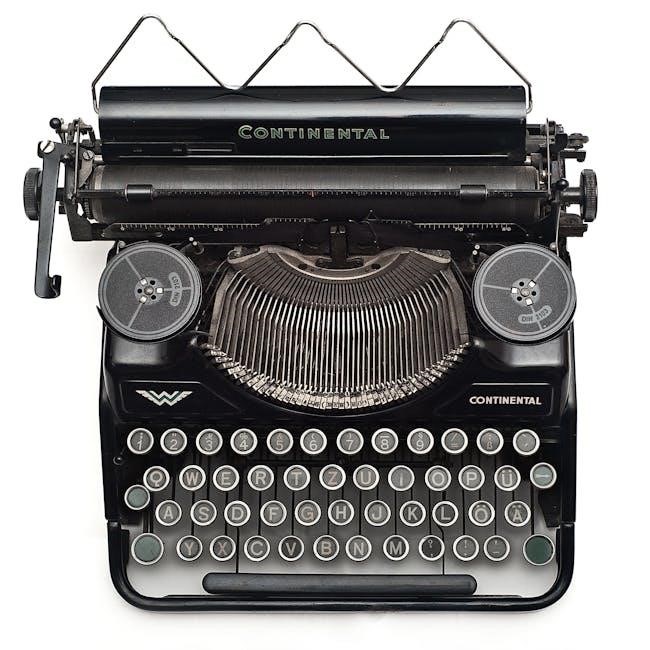

The Hossfeld Bender is a versatile and durable machine designed for bending round tubing, square tubing, and flat bars with precision. Known for its robust construction, it is widely used in various industries for creating accurate bends. The No. 2 Hossfeld Universal Bender is particularly popular, offering a fully operable setup right out of the box. It comes with basic tooling for standard bends and supports both manual and hydraulic operations. Its design allows for smooth transitions between different materials and bending styles, making it a reliable choice for professionals and hobbyists alike. The machine’s ease of use and adaptability ensure efficient bending processes.

Importance of the Manual for Safe and Efficient Operation

The Hossfeld Bender Manual is essential for ensuring safe and efficient operation. It provides detailed instructions for setup, maintenance, and troubleshooting, helping users avoid accidents and machine damage. The manual outlines proper techniques for bending various materials, including round tubing, square tubing, and flat bars. By following the guidelines, users can achieve precise bends while extending the machine’s lifespan. It also covers safety precautions, such as handling hydraulic attachments and wearing protective gear. Without the manual, operators may miss critical steps, leading to suboptimal performance or hazards. Adhering to the manual ensures optimal results and longevity of the Hossfeld Bender.

Setup and Installation

Proper setup ensures the Hossfeld Bender operates accurately. Begin with unboxing and inspection, then mount the machine securely. Complete initial adjustments for alignment and stability to guarantee precise bending operations.

Unboxing and Initial Inspection

Unboxing the Hossfeld Bender reveals a fully assembled machine ready for mounting. Inspect the unit for damage, ensuring all components, including tooling, are included. Verify the main frame and swinging frame are securely connected with a single pin. Check for proper alignment and any signs of shipping damage. The bender arrives pre-trued, simplifying initial setup. Familiarize yourself with the basic tooling provided for standard bends. Before mounting, ensure all parts are accounted for and undamaged. This step ensures smooth operation and prevents future issues. Careful inspection guarantees the bender is ready for safe and efficient use.

MOUNTING the Bender

MOUNTING the Hossfeld Bender is straightforward, as it arrives fully assembled and trued. Secure the main frame to a sturdy workbench or stand using appropriate fasteners to ensure stability. Align the swinging frame with the main frame and connect them using the provided single pin. Ensure the connection is tight to maintain proper alignment. The bender is designed for immediate use after mounting, requiring no additional assembly beyond unpacking and securing it. Follow the manual’s guidelines for proper mounting to ensure safe operation and optimal performance. Proper mounting is crucial for achieving accurate bends and preventing machine damage.

Initial Setup and Adjustments

After mounting, perform initial setup and adjustments to ensure precise operation. Familiarize yourself with the tooling and dies provided, selecting the appropriate ones for your tubing size. Adjust the dies according to the manual’s specifications to achieve the desired bend radius. Lubricate moving parts as recommended to reduce friction and wear. Fine-tune the alignment of the swinging frame to ensure even pressure distribution during bending. Test the machine with a scrap piece to verify proper function and make any necessary adjustments. Proper setup is essential for achieving accurate bends and extending the machine’s lifespan. Follow the manual’s guidelines for optimal performance.

Operating the Hossfeld Bender

Operate the Hossfeld Bender hydraulically or manually for precise bends. Use it to bend round or square tubing, flat bars, and create U-bends or irregular shapes efficiently.

Basic Bending Techniques

Mastering basic bending techniques with the Hossfeld Bender ensures precision and safety. Start by aligning the tubing or bar with the die set, ensuring proper fit and alignment. Secure the material firmly in place to avoid slippage during bending. Apply steady pressure, either manually or hydraulically, depending on the model. For square tubing and flat bars, use the feed-along tooling to maintain consistent bends. Always follow the manual’s guidelines for specific tubing sizes and minimum inside radii. Practice with small angles to build confidence and accuracy. Refer to the manual for detailed diagrams and step-by-step instructions tailored to your Hossfeld Bender model.

Hydraulic vs. Manual Operation

The Hossfeld Bender offers both hydraulic and manual operation options, each with unique advantages. Hydraulic operation provides faster and more precise bending, especially for heavy-duty tasks, while manual operation is ideal for smaller projects and offers greater portability. The hydraulic system reduces physical effort, enabling consistent bends with minimal strain. Manual operation relies on mechanical leverage, requiring more strength but maintaining simplicity and cost-effectiveness. Both modes ensure accurate results when used correctly. The manual recommends starting with manual operation to gain familiarity before transitioning to hydraulic for efficiency. Always follow safety guidelines for either method to ensure optimal performance and durability of the bender;

Step-by-Step Guide to Making Accurate Bends

For precise bends, start by ensuring the bender is properly set up and aligned. Select the appropriate die for your tubing size and material. Clamp the tubing securely, aligning it with the bending die. For manual operation, apply steady pressure to the handle, while hydraulic models require activating the pump. Use a protractor to monitor the bend angle and stop when the desired angle is reached. Release pressure slowly to avoid springback. Always follow the manual’s specific guidelines for different materials and thicknesses. Regular lubrication of moving parts ensures smooth operation and accurate results. Practice on scrap material to refine your technique.

Tooling and Die Selection

Proper tooling and die selection are crucial for achieving precise bends. The Hossfeld Bender supports feed-along type tooling for various tubing sizes, ensuring accurate and efficient bending operations.

Understanding Feed-Along Type Tooling

Feed-along type tooling is designed for precise bending of rectangular tubing and flat bars. It ensures consistent material feeding, reducing the risk of deformation. This tooling is ideal for edge bending and maintains tight tolerances, especially for complex shapes. Proper alignment and setup are essential for optimal performance, as outlined in the Hossfeld manual. Regular maintenance of the tooling ensures longevity and accuracy in bends. By following the manual’s guidelines, users can achieve professional-grade results efficiently.

Die Sets for Specific Tubing Sizes

Die sets are tailored to specific tubing sizes, ensuring precise bends and minimizing material stress. The Hossfeld manual details compatible die sets for various tubing dimensions, such as 3/4 x 1-1/2 inches and 1 x 2 inches. Proper die selection is crucial for achieving accurate results and preventing damage. The manual provides charts and guidelines to help users choose the right die for their project. Regular inspection and maintenance of die sets are also emphasized to ensure optimal performance and longevity.

Setting Up Dies for Optimal Performance

Proper die setup is crucial for achieving accurate bends and extending tool life. Begin by ensuring the die is clean and free from debris. Align the die with the machine’s centerline, securing it firmly to prevent shifting during operation. Refer to the manual for specific torque values to avoid over-tightening, which can damage the die or machine. For feed-along type tooling, ensure the die is properly seated and aligned with the bending arm. Regular lubrication of moving parts is also recommended to maintain smooth operation. Always follow the manual’s guidelines for die setup to ensure precise, repeatable bends and optimal performance. Proper alignment prevents damage and ensures safety.

Maintenance and Troubleshooting

Regular maintenance ensures optimal performance and longevity. Lubricate moving parts, inspect wearable components, and address issues promptly. Troubleshooting guides help resolve common operational problems efficiently and safely.

Regular Maintenance Schedule

Regular maintenance is essential to ensure the Hossfeld Bender operates smoothly and prolongs its lifespan. Start with daily inspections, checking for wear on dies, tooling, and hydraulic components. Lubricate moving parts regularly to prevent friction and corrosion. Clean the machine thoroughly after use to remove debris and metal shavings. Weekly, inspect the hydraulic system for leaks or damage. Monthly, check the alignment of the bending dies and adjust if necessary. Replace worn parts promptly, and ensure all bolts and fasteners are tightened securely. Following this schedule ensures optimal performance, reduces downtime, and maintains precision in bending operations.

Troubleshooting Common Issues

Identifying and addressing common issues with the Hossfeld Bender ensures uninterrupted operation. Inconsistent bends may result from misaligned dies or improper tooling setup. Hydraulic leaks can occur due to worn seals or loose connections, requiring immediate attention to prevent system damage. If the machine fails to bend accurately, check for worn or damaged dies and replace them as needed. Lubrication issues can cause stiffness in moving parts, so ensure all components are properly greased. For electrical or hydraulic malfunctions, consult the manual or contact a professional. Regular inspections and timely repairs help maintain performance and extend the machine’s lifespan.

Replacement of Wearable Parts

Regular replacement of wearable parts ensures optimal performance and longevity of the Hossfeld Bender. Key components like dies, seals, and pins should be inspected frequently. Worn dies can lead to imprecise bends, while damaged seals may cause hydraulic leaks. Replace these parts with genuine Hossfeld components to maintain compatibility and functionality. Proper lubrication of moving parts, such as bushings and hinges, prevents excessive wear. Timely replacement of these elements minimizes downtime and prevents further damage to the machine. Always follow the manual’s guidelines for part replacement to ensure safe and efficient operation.

Safety Guidelines

Always wear protective gear and ensure proper handling of hydraulic attachments. Follow manual instructions to prevent accidents and maintain a safe working environment with the Hossfeld Bender.

Proper Handling of Hydraulic Attachments

Proper handling of hydraulic attachments is crucial for safe operation. Always wear protective gear and ensure the machine is securely mounted. Before use, inspect attachments for damage or leaks. Connect hydraulic components correctly, following the manual’s guidelines. Never operate the bender near flammable materials or in hazardous environments. Keep loose clothing and long hair tied back to avoid entanglement. Regularly inspect hydraulic lines for signs of wear and maintain proper fluid levels. Follow the manual’s instructions for attaching and detaching components to prevent accidents. Proper handling ensures efficient and safe bending operations with the Hossfeld Bender.

Advanced Bending Techniques

Mastering advanced bending techniques with the Hossfeld Bender allows for creating intricate shapes like U-bends and irregular forms. This section explores methods for bending square tubing and flat bars efficiently, ensuring precision and consistency in complex projects.

Bending Square Tubing and Flat Bar

Bending square tubing and flat bar with the Hossfeld Bender requires precise setup and the right tooling. The machine efficiently handles materials like 3/4 x 1-1/2 and 1 x 2 tubing. Use specific die sets for square tubing to maintain the inside radius and avoid deformation. For flat bars, ensure proper alignment and secure clamping to achieve accurate bends. The feed-along type tooling is ideal for edge bending, providing consistent results. Always refer to the manual for recommended die configurations and bending techniques to ensure optimal performance and prevent damage to the material or machine.

Creating U-Bends and Irregular Shapes

Creating U-bends and irregular shapes with the Hossfeld Bender requires precise die selection and careful setup. The manual provides step-by-step guidance for achieving accurate U-bends, ensuring consistent results. For irregular shapes, the machine’s versatility allows for custom configurations, enabling complex bends with ease. Proper tooling alignment and gradual bending techniques are essential to avoid material deformation. The feed-along type tooling supports smooth transitions, making it ideal for intricate shapes. By following the manual’s instructions, users can master these advanced techniques, ensuring precise and professional-grade bends every time.

The Hossfeld Bender Manual is an essential resource for mastering the operation, maintenance, and troubleshooting of the Hossfeld Universal Bender. By following the guidelines outlined in this manual, users can ensure safe, efficient, and precise bending operations. From basic setup to advanced techniques, the manual provides comprehensive instructions to help users achieve professional-grade results. Regular maintenance and proper tooling selection are emphasized to extend the machine’s lifespan and optimize performance. With this manual, operators can confidently tackle a wide range of bending tasks, from simple curves to complex shapes, ensuring accuracy and reliability every time.