Copper pipe size charts are essential tools for selecting the right tubing for plumbing, HVAC, and industrial systems. They provide detailed dimensions, thicknesses, and ratings to ensure proper installation and safety.

What is a Copper Pipe Size Chart?

A copper pipe size chart is a reference guide detailing the dimensions, wall thicknesses, and ratings of copper tubing. It provides essential information for selecting the correct pipe size, ensuring compatibility with specific applications. The chart typically includes measurements such as outside diameter, inside diameter, and wall thickness, along with pressure and temperature ratings. This tool is widely used in plumbing, HVAC, and industrial settings to ensure proper system design and safety. By referring to a copper pipe size chart, professionals can accurately determine the appropriate tubing for their needs, avoiding issues related to flow rate, pressure, and material durability. It serves as a critical resource for installations requiring precise specifications.

Importance of Using Copper Pipe Size Charts

Using copper pipe size charts ensures accurate tubing selection, preventing system inefficiencies and safety hazards. Proper sizing guarantees optimal flow rates and pressure handling, reducing the risk of leaks or bursts. It also aids in compliance with industry standards and regulations, crucial for legal and safety requirements. Incorrect pipe sizing can lead to increased energy costs, premature wear, and potential system failures. By referencing these charts, professionals can avoid such issues, ensuring reliable and long-lasting installations. This makes copper pipe size charts indispensable for achieving efficient, safe, and cost-effective plumbing and HVAC systems, ultimately protecting investments and ensuring user satisfaction.

Understanding Copper Pipe Sizing

Copper pipe sizing is critical for ensuring proper flow rates, pressure handling, and system compatibility. It involves selecting the right diameter and wall thickness for specific applications, ensuring optimal performance and safety.

Nominal Pipe Size (NPS) vs. Tube Size (CTS)

Nominal Pipe Size (NPS) and Copper Tube Size (CTS) are two common measurement systems for copper piping. NPS is based on nominal diameters, often not matching the actual size, while CTS is designed specifically for copper tubing, adhering to standard dimensions. NPS is widely used in industrial and commercial plumbing, focusing on compatibility with fittings and other piping materials. In contrast, CTS is primarily used in residential and HVAC applications, where precise sizing is crucial for water supply and heating systems. Understanding the differences is vital for selecting the correct pipe size, ensuring system efficiency and safety. Proper sizing prevents issues like pressure drops or leaks, ensuring optimal performance in various applications. Always refer to a copper pipe size chart to ensure accurate measurements and compliance with industry standards.

Common Copper Pipe Sizes and Dimensions

Copper pipes are available in various sizes, with the most common ranging from 1/4″ to 4″ in diameter; These sizes are standardized to ensure compatibility and ease of installation. The actual outside diameters (OD) for copper pipes typically range from 0.25 inches for 1/4″ tubing to 4.0 inches for larger industrial applications. Wall thicknesses vary, with Type K, L, and M being the most frequently used, offering different pressure ratings. Type K has the thickest walls, suitable for high-pressure systems, while Type M is thinner, ideal for residential water lines. Referencing a copper pipe size chart provides precise measurements for inner diameter, outer diameter, and wall thickness, ensuring the correct selection for specific applications. This accuracy is crucial for maintaining system performance and safety standards.

Factors Determining Copper Pipe Size

Pressure, temperature, flow rate, and system requirements are key factors in selecting the appropriate copper pipe size. Proper sizing ensures efficiency, safety, and longevity of the system.

Pressure and Temperature Ratings

Pressure and temperature ratings are critical when selecting copper pipes. Charts typically outline maximum allowable pressure based on temperature, ensuring the pipe can handle specific conditions without failure. Higher temperatures often require thicker-walled pipes to maintain strength and prevent bursting. For instance, a pipe rated for 100 PSI at 70°F may only be rated for 75 PSI at 200°F. Proper matching of pressure-temperature ratings ensures system safety and longevity. Always refer to the specific copper pipe size chart for precise data, as ratings can vary by manufacturer and pipe type. This ensures optimal performance under varying operational conditions.

Flow Rate and Velocity Considerations

Flow rate and velocity are key factors in selecting the appropriate copper pipe size. A larger pipe diameter allows for higher flow rates, reducing pressure drop and energy losses. However, oversized pipes can increase material and installation costs. Velocity, measured in feet per second, should be kept within recommended limits to prevent erosion, noise, and vibration. For water systems, typical velocity ranges are 2-8 feet per second, while for steam or gas, higher velocities may be acceptable. Proper balancing of flow rate and pipe size ensures efficient system performance and longevity. Always consult copper pipe size charts to match flow requirements with the correct tubing specifications for optimal results.

Applications of Copper Pipe Size Charts

Copper pipe size charts are crucial for plumbing, HVAC systems, and industrial setups, ensuring correct tubing selection for safe and efficient fluid and gas transport.

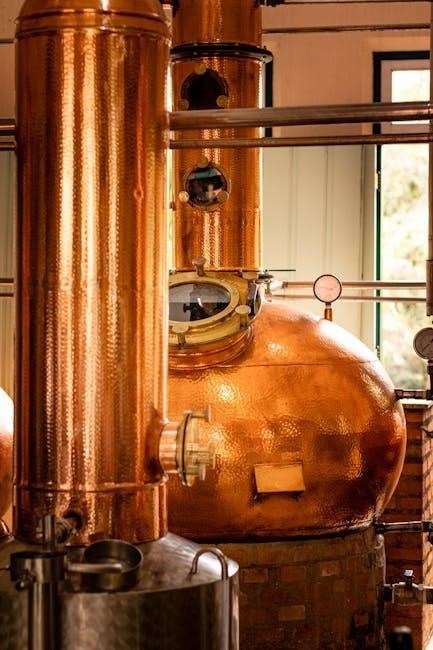

Plumbing and Water Supply Systems

Copper pipe size charts are indispensable in plumbing and water supply systems, helping to determine the appropriate tubing for water distribution and drainage. They provide precise measurements for pipe diameters, wall thicknesses, and maximum pressure ratings, ensuring reliable water flow and system integrity. By referencing these charts, plumbers can select the correct pipe sizes to meet specific water pressure and flow rate requirements, preventing leaks and ensuring long-term durability. Additionally, copper’s resistance to corrosion and high thermal conductivity makes it a preferred material for both hot and cold water systems, further emphasizing the importance of accurate pipe sizing for optimal performance.

Heating, Ventilation, and Air Conditioning (HVAC)

Copper pipe size charts are crucial for HVAC systems, particularly in refrigeration and hydronic heating applications. They help determine the optimal tubing size for efficient heat transfer and fluid flow. By referencing these charts, technicians can ensure proper sizing for varying pressure and temperature conditions, which is essential for maintaining system performance and longevity. Copper’s excellent thermal conductivity and durability make it a preferred choice for HVAC installations, including steam and hot water distribution systems. Accurate pipe sizing prevents issues like reduced airflow, excessive noise, or system inefficiencies, ensuring reliable operation in both residential and commercial HVAC setups.

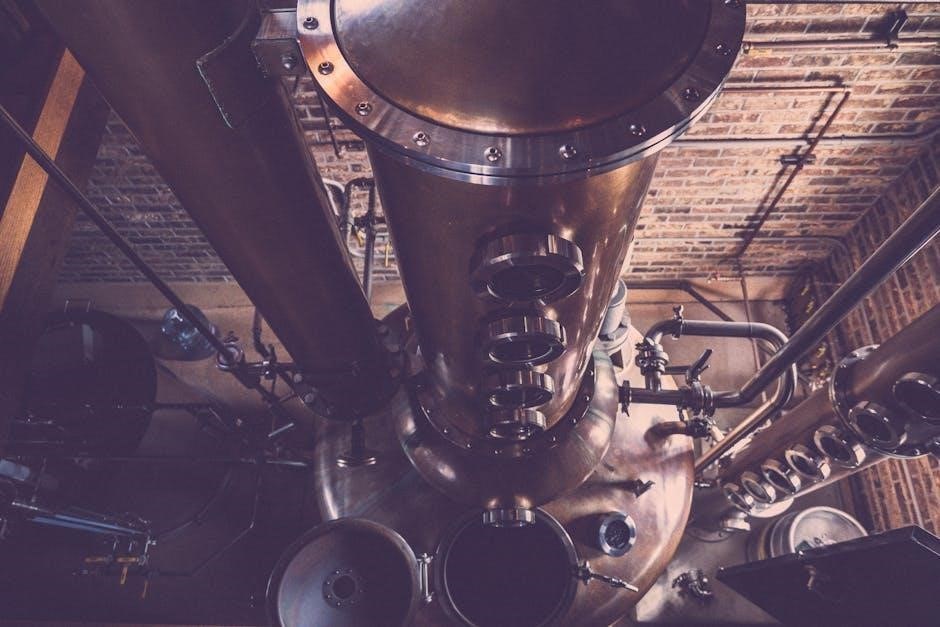

Industrial and Commercial Uses

Copper pipe size charts are indispensable in industrial and commercial settings where precise tubing specifications are critical. In manufacturing, chemical processing, and power generation, copper’s durability and resistance to corrosion ensure reliable performance. These charts help engineers and technicians select the appropriate pipe sizes for high-pressure and high-temperature applications, minimizing risks of leaks or system failures. Additionally, copper piping is widely used in commercial facilities for water distribution, gas lines, and fire suppression systems. By adhering to standardized size charts, professionals can ensure compliance with industry regulations and optimize system efficiency. Proper sizing also reduces maintenance costs and extends the lifespan of industrial and commercial infrastructure.

How to Read a Copper Pipe Size Chart

A copper pipe size chart simplifies selecting the right tubing by detailing nominal sizes, actual dimensions, wall thicknesses, and pressure ratings, ensuring compatibility and safety for installations.

Understanding the Chart Layout

A copper pipe size chart is organized into columns, typically including nominal pipe size, outside diameter, wall thickness, and pressure ratings. The layout may vary slightly between manufacturers or standards, but the core information remains consistent. Each row represents a specific pipe size, making it easy to compare dimensions and ratings side by side. The charts often include both imperial and metric measurements to cater to different regions and applications. Understanding the layout allows users to quickly identify the required specifications for their project, ensuring accurate selection and compliance with engineering standards. This clarity is essential for efficient planning and installation.

Selecting the Right Pipe Size for Your Needs

Selecting the appropriate copper pipe size involves considering factors like flow rate, pressure, and temperature. Refer to the chart to match your system requirements with the pipe’s specifications. Ensure the pipe’s diameter and wall thickness align with the application’s demands. For high-pressure or high-temperature environments, thicker-walled pipes are recommended. Additionally, account for the desired flow velocity to prevent turbulence and erosion. Using the chart, cross-reference these variables to identify the optimal pipe size, ensuring efficient performance and longevity of the system. Proper selection prevents issues like pressure drops or leaks, making it a critical step in system design and installation.

Sources for Copper Pipe Size Chart PDF

Official standards like ASTM and ASME provide reliable copper pipe size charts. Manufacturers offer specific resources, and online databases like Engineering Toolbox host comprehensive guides.

Official Standards and Specifications

Official standards like ASTM and ASME provide authoritative copper pipe size charts. These documents define dimensions, wall thicknesses, and pressure ratings, ensuring compliance with safety and performance requirements. ASTM B88 outlines seamless copper tubes for plumbing, while ASME B36.19 covers dimensions for copper pipe fittings. These standards are regularly updated to reflect industry advancements. They are widely recognized and adhere to strict testing protocols, making them indispensable for engineers and contractors. By referencing these standards, professionals ensure their systems meet quality and safety benchmarks, reducing risks of failures and ensuring optimal performance. These resources are available as PDFs for easy access and reference.

Manufacturer-Provided Resources

Many copper pipe manufacturers offer detailed size charts and specifications in PDF format. These resources are tailored to their products, ensuring accurate dimensions and ratings. Companies like Mueller Industries and NIBCO provide comprehensive guides, including data on pipe sizes, wall thicknesses, and pressure ratings. These charts often include additional information such as material grades and recommended applications. They are designed to help customers select the right products for their specific needs. Manufacturer-provided resources are typically available on their official websites for easy download. By using these charts, users can ensure compatibility and performance, aligning with the manufacturer’s quality standards. This direct access streamlines the selection process for engineers and contractors.

Online Databases and Engineering Tools

Online databases and engineering tools provide convenient access to copper pipe size charts in PDF format. Platforms like ASHRAE, ASTM, and the Copper Development Association offer detailed charts and technical specifications. Engineering tools such as pipe sizing calculators and simulation software often include copper pipe size data for precise system design. These resources allow users to filter by pipe size, wall thickness, and pressure rating, ensuring compliance with industry standards. Many databases also provide cross-references to manufacturer specifications, making it easier to find compatible products. Additionally, online libraries like Engineering Toolbox and Copper.org host extensive collections of copper pipe charts, serving as invaluable references for engineers and contractors. These tools streamline the selection process, ensuring optimal system performance and safety.

Copper pipe size charts are indispensable for ensuring proper system design, efficiency, and safety. Utilizing accurate sizing and specifications guarantees optimal performance and compliance with industry standards.

The Importance of Accurate Pipe Sizing

Accurate copper pipe sizing ensures efficient fluid flow, reduces pressure drops, and prevents system failures. Proper sizing minimizes leaks, corrosion, and energy losses, optimizing performance and longevity. Using charts helps avoid undersizing, which can lead to reduced flow rates and increased wear, or oversizing, which raises material and installation costs. Correct sizing also ensures compliance with safety and regulatory standards, critical for both residential and industrial applications. By referencing detailed copper pipe size charts, professionals can select tubing that meets specific pressure, temperature, and flow requirements, ensuring reliable and durable systems. This precision is vital for maintaining safety, efficiency, and cost-effectiveness in all piping installations.